Servicing, Overhauling, and Repairing of HT & LT BOCBs, VCBs, ACBs, and SF6 Breakers up to 33 KV

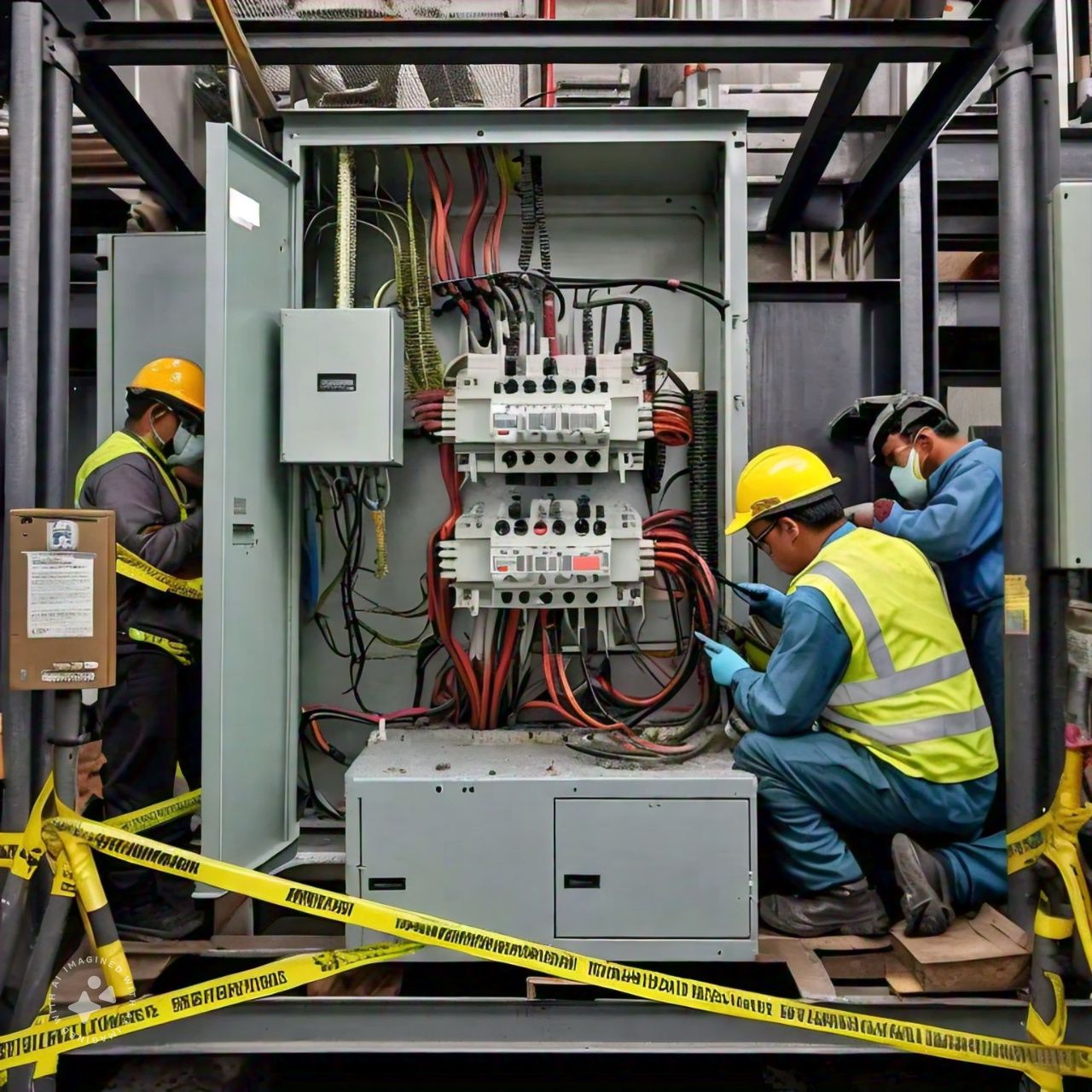

High Tension (HT) and Low Tension (LT) circuit breakers such as Bulk Oil Circuit Breakers (BOCBs), Vacuum Circuit Breakers (VCBs), Air Circuit Breakers (ACBs), and SF6 Breakers are critical components in electrical systems, providing protection and control. Proper servicing, overhauling, and repairing of these breakers ensure the reliability and safety of electrical networks. This guide outlines the processes and best practices for maintaining these breakers up to 33 kV.

Servicing

Regular servicing is essential to maintain the performance and extend the lifespan of circuit breakers.

Visual Inspection:

-

- Inspect for signs of wear, corrosion, or physical damage.

- Check for loose connections, burnt contacts, and mechanical defects.

Cleaning:

-

- Clean all components, including contacts, terminals, and insulating parts.

- Use appropriate cleaning agents to remove dust, dirt, and contaminants.

Lubrication:

-

- Apply suitable lubricants to moving parts such as operating mechanisms and hinges.

- Ensure lubrication is performed as per the manufacturer’s recommendations.

Tightening Connections:

-

- Tighten all electrical and mechanical connections to prevent overheating and arcing.

- Verify torque settings to ensure proper connection without over-tightening.

Operational Testing:

-

- Test the mechanical operation of the breaker, including opening and closing cycles.

- Verify that the breaker operates smoothly without undue friction or resistance.

Overhauling

Overhauling involves a more comprehensive examination and refurbishment of circuit breakers. It is typically performed at scheduled intervals or when the breaker shows signs of significant wear or malfunction.

Disassembly:

-

- Carefully disassemble the breaker, following manufacturer guidelines.

- Document the disassembly process to ensure accurate reassembly.

Detailed Inspection:

-

- Inspect all components for wear, damage, and alignment.

- Use magnification tools to examine contact surfaces and insulating materials.

Component Replacement:

-

- Replace worn or damaged components, such as contacts, springs, and seals.

- Use genuine or manufacturer-approved parts to maintain performance standards.

Reconditioning:

-

- Recondition reusable components by cleaning, polishing, and restoring them to their original condition.

- Apply protective coatings to prevent corrosion and extend component life.

Reassembly and Adjustment:

-

- Reassemble the breaker, ensuring all parts are correctly aligned and fitted.

- Adjust settings such as contact gap, spring tension, and trip mechanisms according to specifications.

Repairing

Repairing circuit breakers involves diagnosing and fixing specific faults that affect their performance.

Fault Diagnosis:

-

- Identify the root cause of the malfunction through inspection and testing.

- Use diagnostic tools such as insulation resistance testers, continuity testers, and thermal cameras.

Component Repair or Replacement:

-

- Repair or replace faulty components, such as damaged contacts, worn springs, or defective control units.

- Ensure that repaired components meet the required performance standards.

Circuit Repair:

-

- Address issues in the breaker’s control and protection circuits.

- Verify the integrity of wiring, connections, and insulation.

Post-Repair Testing:

-

- Conduct comprehensive tests to verify the effectiveness of the repairs.

- Perform insulation resistance testing, contact resistance measurement, and functional testing.