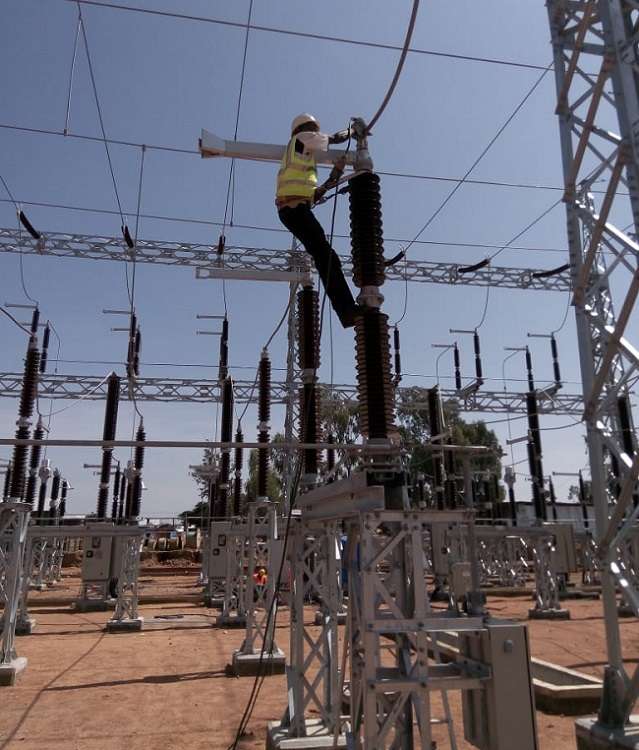

Erection, Testing, and Commissioning of Sub-Stations up to 33 KV.

The erection, testing, and commissioning of sub-stations up to 33 kV are essential processes in establishing a reliable electrical power distribution network. Sub-stations are pivotal in transforming voltage levels to ensure efficient power transmission and distribution. This guide details the comprehensive steps involved in erecting, testing, and commissioning sub-stations up to 33 kV, ensuring their optimal performance and safety.

Erection

The erection of a sub-station involves the construction and assembly of various components, ensuring they are correctly installed and aligned with design specifications.

Site Preparation:

-

- Conduct a site survey to determine the suitability of the location.

- Clear the site of any obstructions and level the ground.

- Lay the foundation according to the structural design, ensuring it can support the sub-station equipment.

Equipment Installation:

-

- Install primary equipment, including transformers, circuit breakers, isolators, and switchgear.

- Position and secure auxiliary equipment such as control panels, battery banks, and protective relays.

- Erect steel structures for supporting busbars and other high-voltage equipment.

Busbar and Conductor Installation:

-

- Install busbars and connect them to the transformers and switchgear.

- Ensure proper tensioning and alignment of conductors to prevent sagging and maintain electrical clearances.

Grounding System:

-

- Implement a robust grounding system to ensure safety and prevent electrical hazards.

- Connect all equipment and structures to the grounding grid to provide a path for fault currents.

Cable Laying and Termination:

-

- Lay power cables, control cables, and communication cables in designated trenches or conduits.

- Terminate cables at their respective equipment, ensuring secure and reliable connections.

Testing

Testing is a critical phase to verify the functionality and safety of the sub-station components before commissioning.

Insulation Resistance Testing:

-

- Measure the insulation resistance of transformers, circuit breakers, and cables to ensure they are free from moisture and contamination.

High-Pot Testing:

-

- Perform high-potential (Hi-Pot) tests on high-voltage equipment to verify the integrity of insulation and detect any weaknesses.

Transformer Testing:

-

- Conduct tests such as turns ratio, polarity, and vector group to ensure transformers are correctly assembled and operational.

- Perform oil tests to check for dielectric strength and contaminants.

Circuit Breaker Testing:

-

- Test the operation of circuit breakers, including timing tests for opening and closing times.

- Verify the trip settings and protective relay coordination.

Functional Testing:

-

- Test the entire system under simulated load conditions to ensure all components function correctly.

- Verify the operation of protection schemes, interlocks, and alarms.

Commissioning

Commissioning is the final step to ensure the sub-station is ready for operation. It involves comprehensive checks and validations:

Pre-Commissioning Checks:

-

- Verify that all equipment is installed according to design specifications.

- Check for any loose connections, mechanical defects, or other installation issues.

System Integration Testing:

-

- Test the integration of all sub-station components to ensure they work harmoniously.

- Validate the operation of SCADA (Supervisory Control and Data Acquisition) systems for remote monitoring and control.

Performance Verification:

-

- Conduct load tests to verify the performance of transformers, breakers, and other equipment under actual operating conditions.

- Monitor system parameters such as voltage, current, and temperature to ensure they are within acceptable limits.

Safety and Protection Testing:

-

- Test the operation of all protective devices and safety mechanisms.

- Ensure all safety protocols and procedures are in place and functional.

Final Documentation and Handover:

-

- Compile detailed documentation of all tests, results, and configurations.

- Provide a comprehensive handover package to the operation and maintenance team, including operation manuals and maintenance schedules.